Pipeline Manufacturer best practices for material selection

Wiki Article

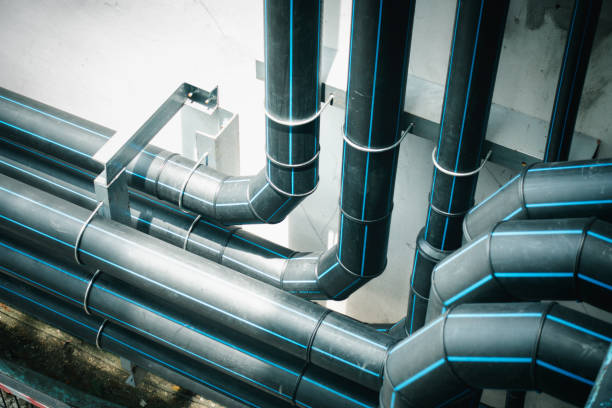

Pipeline Manufacturer Spotlight: Discover the Best in the Market for Your Following Project

In the domain of pipeline manufacturing, the option of producer can significantly impact the result of your task. With a selection of business offering advanced products and innovative remedies, comprehending the vital criteria for option ends up being essential. Market leaders like Tenaris, Vallourec, and United State Steel are at the center of giving trustworthy and lasting options. The concern stays: what certain aspects should direct your decision-making procedure, and exactly how do these makers separate themselves in an increasingly competitive market? Exploring these aspects may disclose understandings that could affect your next job's success.Market Summary

In the pipeline manufacturing field, there exists a vibrant interaction of technical advancements and regulative demands that forms sector methods. This market is crucial for the transportation of oil, gas, water, and other liquids, necessitating a robust understanding of both product residential properties and ecological impacts. Manufacturers are significantly integrating sophisticated materials and innovative manufacturing strategies to enhance the longevity and effectiveness of pipes, guaranteeing they can endure varying pressures and ecological problems.

On top of that, the increase of digital technologies has actually transformed traditional manufacturing processes, permitting enhanced surveillance and predictive maintenance. This shift not just improves functional effectiveness however also aids in mitigating possible failures prior to they intensify into essential concerns. Overall, the landscape of pipeline manufacturing is identified by a constant evolution driven by advancement and compliance, placing the industry for future development and sustainability.

Key Criteria for Option

Selecting the right pipeline manufacturer includes cautious consideration of numerous key criteria that assure dependability, performance, and compliance with sector standards. Primarily, examine the maker's experience and track record within the sector. A well-established firm with a proven performance history is much more likely to provide top quality products and solutions.Next off, review the variety of specs and products offered. Manufacturers ought to give a selection of options that satisfy diverse job demands, consisting of various pipeline sizes, materials, and covering systems. Conformity with pertinent industry standards, such as ASTM or API, is important, as it guarantees the products satisfy safety and performance benchmarks.

Furthermore, think about the supplier's technical abilities. Advanced production techniques and quality assurance actions can greatly impact the toughness and efficiency of the pipes. Customer solution and support are additionally essential; a responsive and experienced group can facilitate smoother job execution and resolve any worries immediately.

Assess pricing frameworks and lead times. While cost-effectiveness is necessary, it must not jeopardize quality. Balancing these standards will certainly cause a knowledgeable choice that straightens with project objectives and regulative needs.

Leading Pipeline Manufacturers

In the competitive landscape of pipeline manufacturing, several sector leaders stand out for their ingenious innovations and dedication to sustainability. These top makers not just master delivering high-quality products but also prioritize ecologically responsible techniques in their procedures. An overview of their contributions supplies important insights right into the future of pipeline solutions.Market Leaders Overview

How do market leaders form the pipeline manufacturing landscape? The leading pipeline manufacturers play a vital role in developing industry requirements, driving technology, and assuring quality control throughout the supply chain. Companies such as Tenaris, Vallourec, and U.S. Steel have established criteria for security, sustainability, and performance, affecting not just their procedures yet also their rivals.These leaders invest significantly in r & d to boost product longevity and performance. Their commitment to sticking to regulatory conformity and global standards cultivates consumer trust fund and encourages industry-wide adoption of finest methods. Furthermore, they typically team up with stakeholders, consisting of engineers and building companies, to ensure that their products fulfill particular job requirements and ecological factors to consider.

Market leaders additionally focus on consumer partnerships, supplying customized services and extraordinary service, which enhances their market setting. By leveraging economic situations of range, they can supply affordable rates without compromising top quality. Ultimately, the influence of these makers expands beyond their products; they form the future of pipeline modern technology and manufacturing procedures, guaranteeing a lasting and resilient framework for different industries worldwide.

Cutting-edge Technologies Used

What innovative technologies are changing the pipeline manufacturing market? Recently, leading pipeline manufacturers have accepted advanced innovations to boost performance, dependability, and security in their operations. One considerable advancement is the combination of wise pipeline monitoring systems, using Web of Things (IoT) sensors. These systems give real-time information on pipeline conditions, allowing aggressive maintenance and lowering the risk of leaks or failings.

Additionally, suppliers are significantly taking on innovative materials, such as composite pipelines, which supply enhanced longevity and resistance to rust. These materials not just prolong the life-span of pipes but likewise lower functional costs in time. Additionally, additive manufacturing, or 3D printing, is changing the manufacturing procedure. This modern technology permits quick prototyping and modification of parts, improving supply chains and decreasing waste.

Fabricated intelligence (AI) and artificial intelligence formulas are likewise obtaining traction, enhancing style procedures and anticipating upkeep schedules. By assessing large datasets, these modern technologies help determine prospective issues prior to they develop, enhancing security and operational performance. As these ingenious innovations proceed to develop, they promise to form the future of pipeline manufacturing, ensuring that tasks can be finished promptly and within budget plan while maintaining the utmost security standards.

Sustainability Practices Highlighted

The continuous advancements in innovative innovations within the pipeline manufacturing industry are complemented by an expanding focus on sustainability techniques among leading manufacturers. These business are progressively taking on environmentally friendly methods, reducing waste, and decreasing their carbon impacts throughout the manufacturing procedure.Leading makers are focusing on using recycled materials, enhancing the lifecycle of their items. By implementing closed-loop systems, they successfully utilize resources, consequently lessening the ecological effect related to basic material removal and handling. Additionally, many companies are purchasing renewable resource sources to power their operations, even more minimizing greenhouse gas exhausts.

Furthermore, pipeline makers are accepting innovative coatings and materials that enhance deterioration resistance and long life, which inevitably decreases the frequency of substitutes and repair services. These sustainable techniques not just add to environmental stewardship but likewise line up with the growing regulative demands and market assumptions for responsible manufacturing.

Moreover, partnership with stakeholders to foster sustainability initiatives showcases a dedication to a greener future. By concentrating on lasting methods, top pipeline suppliers are not just boosting their operational effectiveness however also setting a criteria for market standards, promoting an extra lasting pipeline facilities for all.

Innovative Technologies

The pipeline market is experiencing a transformative change through the assimilation of innovative technologies, specifically in innovative materials advancement and smart pipeline monitoring systems. These improvements not just enhance the durability and effectiveness of pipes yet additionally enhance safety and security and environmental stewardship. As suppliers embrace these innovative remedies, the future of pipeline infrastructure looks progressively promising.Advanced Materials Growth

Technologies in innovative materials advancement are reinventing the pipeline manufacturing industry, driving improvements in effectiveness, performance, and sturdiness. The emergence of high-strength alloys and composite materials has enabled the production of pipelines that can stand up to extreme conditions, consisting of high stress and corrosive atmospheres. These products not only extend the lifespan of pipes however also reduce upkeep expenses, inevitably leading to boosted functional effectiveness.

Furthermore, improvements in polymer science have actually brought about the production of light-weight, versatile piping systems that are much easier to mount and transport. These developments add to decrease carbon footprints in pipeline tasks, straightening with international sustainability objectives. Furthermore, the combination of nanotechnology in product development is opening up new avenues for enhancing the mechanical properties of standard materials, causing pipes that can endure higher stress while preserving integrity.

As suppliers remain to invest in research study and growth, the pipeline industry is experiencing an unprecedented advancement in material capabilities. This concentrate on innovative products not just supports the expanding demand for trustworthy framework but also cultivates a competitive landscape in which firms can differentiate themselves via superior product offerings. The future of pipeline manufacturing is certainly intertwined with these groundbreaking innovations.

Smart Pipeline Keeping An Eye On Equipments

Smart pipeline tracking systems are transforming the landscape of pipeline administration by integrating advanced technologies such as IoT sensors, expert system, and real-time data analytics. Pipeline Manufacturer. These systems allow drivers to keep an eye on the stability and efficiency of pipelines continually, substantially reducing the danger of leaks and failuresThrough the implementation of IoT sensing units along pipeline paths, operators collect important information on flow, temperature, and stress prices. This information is transferred in real-time to central surveillance systems, permitting instant evaluation and reaction to anomalies. Advanced man-made intelligence algorithms analyze this information to identify patterns, forecast potential problems, and recommend preventative measures prior to they rise right into expensive issues.

The implementation of wise surveillance systems not only improves functional performance yet likewise fosters conformity with regulative criteria. By supplying comprehensive records and insights, these technologies sustain better decision-making and danger monitoring. Additionally, the assimilation of maker learning capacities enables systems to improve over time, adapting to altering conditions and improving anticipating accuracy.

As the market continues to welcome these technologies, clever pipeline monitoring systems are poised to play a crucial duty in ensuring the safety and security, integrity, and sustainability of pipeline facilities. HDPE Pipe Supplier.

Situation Researches of Success

Success tales within the pipeline manufacturing market illuminate the performance of cutting-edge solutions and cooperation among stakeholders. One noteworthy case is the collaboration in between a leading manufacturer and an oil firm to implement an advanced wise pipeline monitoring system. The project considerably reduced leakage detection times and enhanced functional performance, showcasing the value of sophisticated innovation in enhancing safety and decreasing expenses.One more instance involves a supplier that efficiently integrated sustainable materials right into their pipeline building. By working together with research organizations, they created a composite product that is not just durable but additionally eco-friendly. This technology not just met regulative needs but also attracted new clients looking for sustainable solutions.

A pipe task in a challenging geographical area showed the relevance of flexible design methods. The producer worked together with local engineers to develop a pipe that might hold up against extreme climate condition, eventually avoiding solution disruptions and guaranteeing reliability for end-users.

These instance studies exhibit how tactical partnerships, technological developments, and adaptive solutions in the pipeline manufacturing market result in successful task end results, thereby strengthening the industry's commitment to supplying top quality infrastructure while dealing with customer requires properly.

Sustainability Practices

As the pipeline manufacturing market progresses, the assimilation of sustainability techniques has come to be progressively vital. Manufacturers are adopting green materials and processes to reduce their ecological influence while preserving high requirements of high quality and security. This change is driven by both regulative demands and a growing recognition of ecological obligation amongst stakeholders.

One prominent technique is using recycled products in pipeline manufacturing, which lowers the demand for virgin resources and lowers waste. Business are likewise buying try this energy-efficient manufacturing methods, therefore decreasing their carbon impact throughout production. In addition, lots of producers have actually taken on water preservation practices, making sure that water usage is reduced and wastewater is treated effectively.

Sustainable transport methods are being made use of to deliver products, including enhancing logistics to minimize exhausts. The commitment to lifecycle assessments permits manufacturers to assess the ecological influence of their products from beginning to disposal, advertising not only sustainability but additionally long-term financial practicality.

Inevitably, the fostering of sustainability techniques in pipeline manufacturing symbolizes a vital step towards lining up industry procedures with international environmental goals, ensuring that future jobs are both responsible and innovative - American Plastics LLC HDPE Pipe Solutions. - Pipeline Manufacturer

Future Patterns in Pipeline Manufacturing

What developments are on the perspective for pipeline manufacturing? As the sector evolves, numerous crucial patterns are forming the future of pipeline production. Initially, the assimilation of innovative products such as composite pipelines guarantees improved resilience and resistance to deterioration, consequently expanding the life expectancy of pipes. These materials not only reduce maintenance expenses yet additionally boost safety and security criteria.

Sustainability remains a critical focus, with makers significantly prioritizing eco-friendly methods. The development of biodegradable materials and the application of recycling programs are acquiring traction, lining up with worldwide environmental objectives.

Regularly Asked Concerns

What Materials Are Commonly Made Use Of in Pipeline Manufacturing?

Typical products made use of in pipeline manufacturing include carbon steel, stainless-steel, polyethylene, and pliable iron (American Plastics LLC HDPE Pipeline Manufacturer). Each product uses distinct benefits relating to toughness, corrosion resistance, and viability for various applications within the pipeline industryFor how long Does the Pipeline Manufacturing Refine Typically Take?

The pipeline manufacturing procedure generally ranges from a few weeks to numerous months, depending upon elements such as product choice, production capacity, and modification needs. Efficient planning and coordination can substantially influence the overall timeline.What Are one of the most Common Pipeline Sizes Available?

The most usual pipeline sizes range from 2 inches to 48 inches in diameter. Irregularity exists based on specific applications, sector requirements, and local requirements, guaranteeing versatility to meet diverse job needs and operational requirements.Exist Service Warranties Used on Pipeline Products?

Yes, numerous pipeline makers supply guarantees on their products, typically covering material problems and workmanship. The period and regards to these warranties differ by producer, so it is vital to assess particular plans before purchase.Exactly how Do I Make Sure Appropriate Installment of Pipes?

To ensure appropriate installment of pipelines, adhere to industry requirements, use qualified experts, carry out complete site assessments, carry out quality control procedures, and protected compliance with policies. Routine examinations and upkeep even more enhance pipeline efficiency and long life.Pipeline manufacturers are accepting innovative coatings and materials that boost corrosion resistance and durability, which ultimately decreases the regularity of replacements and fixings. The pipeline industry is observing a transformative shift via the assimilation of ingenious modern technologies, particularly in innovative materials advancement and wise pipeline surveillance systems. As producers continue to spend in research and growth, the pipeline sector is witnessing an extraordinary advancement in material capacities. Smart pipeline tracking systems are transforming the landscape of pipeline management by incorporating sophisticated technologies such as IoT sensing units, artificial knowledge, and real-time data analytics. Yes, lots of pipeline makers provide guarantees on their products, usually covering material issues and handiwork.

Report this wiki page